ELECTRICAL

Comprehensive Subsea Electrical Services for Offshore Energy Projects

Reliable electrical power and signal transmission is essential for controlling subsea equipment and enabling accurate data communication in offshore operations.

Subsea cables are routinely used to deliver power to subsea trees, satellite oil and gas platforms, and subsea pumps. Increasingly, these cables also play a key role in the global shift towards clean energy, transferring power from offshore renewable energy installations such as wind farms and tidal generators.

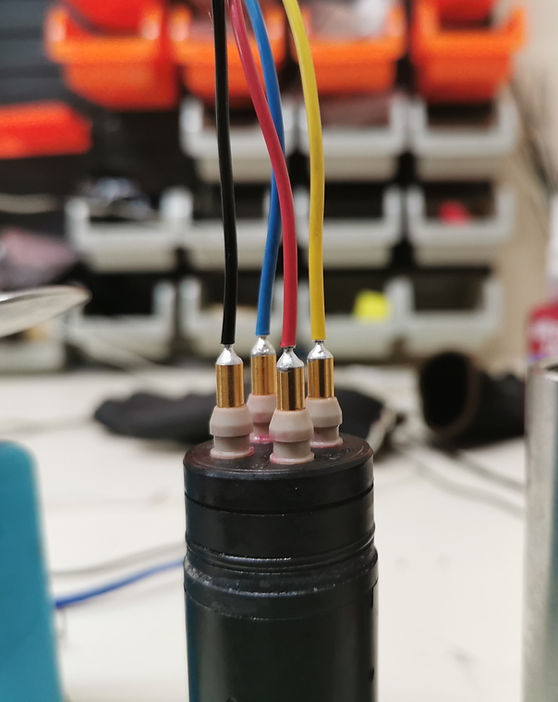

At Legasea, we specialise in providing high-quality subsea electrical solutions for the oil and gas and renewable sectors. We maintain an extensive stock of dry-mate and wet-mate subsea electrical connectors, available in 4-way, 7-way, and 12-way configurations for ROV, diver, or stab plate deployment. All connectors are offered in either new or fully refurbished condition and undergo rigorous helium leak and hyperbaric testing to ensure performance and reliability under extreme subsea conditions.

Our in-house experts perform precision electrical terminations to the internationally recognised IPC/J-STD-001 soldering standard. We offer gel-filled, oil-filled, and moulded subsea connector options, allowing for the manufacture or modification of complex subsea assemblies such as Electrical Flying Leads (EFLs), Jumpers, Umbilicals, and Electrical Distribution Units (EDUs).

Legasea also delivers advanced electrical testing services for all cable types. Our testing protocols include Continuity Resistance (CR), Insulation Resistance (IR), and High Voltage Very Low Frequency (HVVLF) testing to assess cable integrity.

We also perform Time Domain Reflectometry (TDR) testing, which helps identify faults, insulation breakdowns, and water ingress along cable lengths or joints.

To ensure optimal signal performance, we conduct crosstalk testing on multi-core subsea cables. This detects unwanted signal interference between adjacent conductors, which can compromise data quality in control and communication systems. Identifying and addressing crosstalk issues early ensures system reliability and avoids costly downtime during offshore operations.

All services are delivered using specialist test equipment by our highly trained technicians. Where replacement of components is required, we prioritise sourcing through the circular economy, supporting both sustainability and cost-effective operations.

Learn More:

Electrical Downhole Instrumentation